"We specialize in what makes us different."

-Nicholas Valenti, owner B. Nelson Shoes.

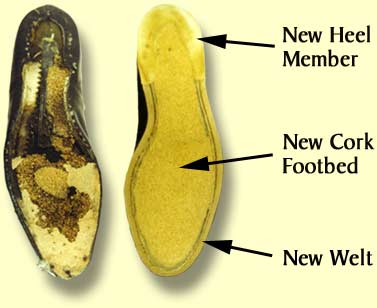

B. Nelson specializes in factory method resoling. Each pair of shoes is fitted with the proper last. The sole is removed, cork footbeds are stripped and replaced, and even welts and heel bases are replaced when necessary. We use a minimum of 19 steps in order to complete our resoling process. Our process is so detail-oriented that we even take the time to pre-grove a channel before stitching the new sole on. This is done so that the stitching of the new sole is below the surface of the leather to allow maximum wear on your repair. The final step is to remove the last so that the original size and shape of the shoe are not altered.

We are the only shoe repair company that uses wooden lasts. Lasts are what all high-grade shoe companies use when manufacturing their products. They vary in 1/2 size increments in both length and width. Repair companies use metal jacks which only come in two men’s sizes: medium and large. This is the reason that in the past you may have experienced a change in the shape of your shoe or perhaps experienced a lumpiness inside. The lumpiness is caused when the repairman shifts or patches the cork footbeds rather than stripping and reapplying them in the way the manufacturers did when the shoe was created. This original process is what B. Nelson Shoes applies in our repair procedure.